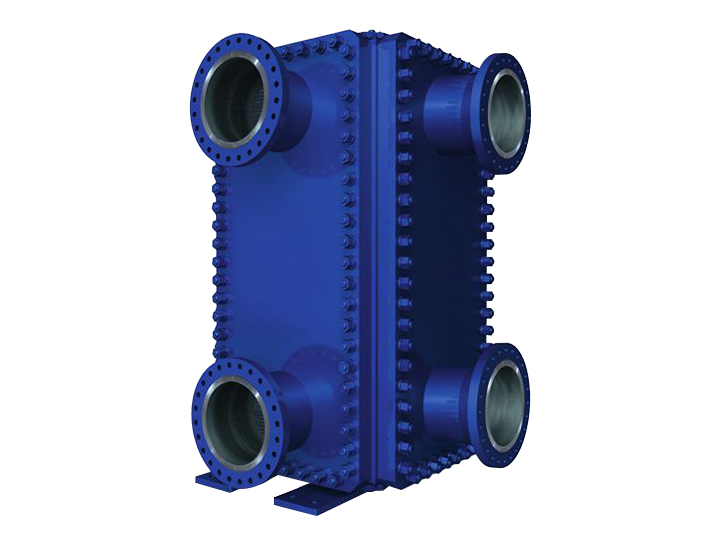

Product description:

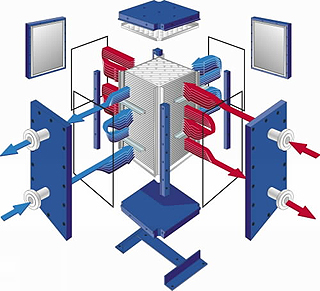

The BLOC plate and frame heat exchanger can be used under high temperature and high pressure conditions. The all welded plates are welded by an advanced laser welding machine, and all the plates are welded in the casing. It can achieve pure countercurrent heat transfer instead of the wrong countercurrent heat transfer of other products, which can produce high turbulence. Under the same working conditions, the efficiency of A-BLOC full-welded heat exchanger is 4 times that of tubular heat exchanger, which means A small area can meet the requirements. At the same time, in the case of large thermal stress applications, the plate group can be stretched in the frame and can have strong thermal shock resistance. The plate-and-frame heat exchanger maintains the advantages of high heat transfer efficiency and compact structure of ordinary plate heat exchangers, and is widely used in petroleum refining, chemical, petrochemical and steel industries.

This highly durable heat exchanger is good at handling aggressive media and media with high fouling content. It can handle aggressive media on both sides and is less susceptible to contamination and clogging, requiring only occasional inspection and cleaning. The entire panel can be flushed from all sides, as all panels on the heat exchanger can be easily removed to meet the demanding conditions of demanding heat exchange.

Features:

Compact structure design and small footprint.

Pure countercurrent heat transfer, high turbulence.

Strong resistance to thermal shock performance.

Clear and easy to maintain.

Application range:

Capacity range: 0.1m3/h to 2500m3/h

Operating pressure: ≤3.5MpaG

Operating temperature: ≤350 °C

Plate material: stainless steel 304, 316L, Ti, Ti-Pd, 904L, SMO254, Hastelloy, nickel Ni.

PRODUCTS

PRODUCTS SOLUTIONS

SOLUTIONS