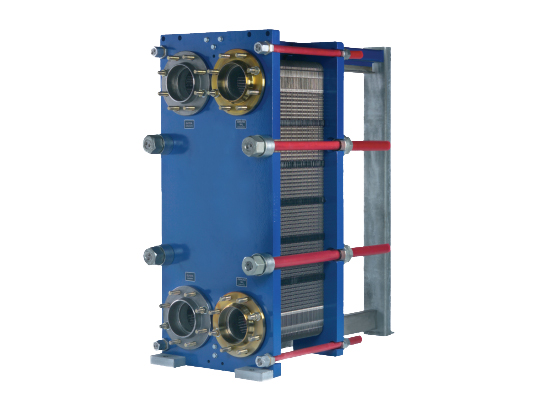

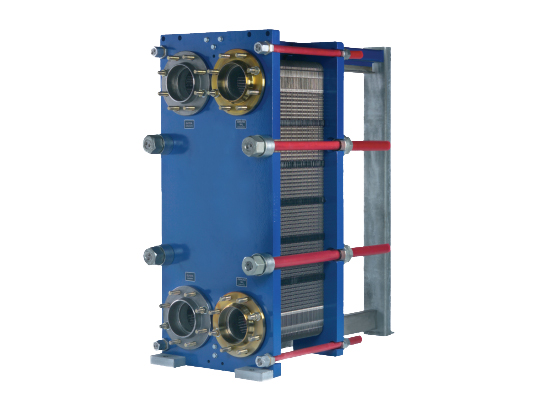

Semi-welded plate heat exchanger

Product description:

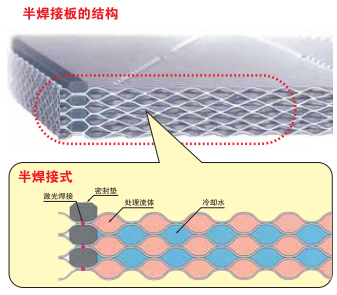

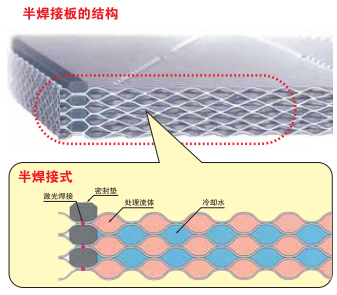

The semi-welded plate heat exchanger is a method in which two plates are laser welded to a plate along a sealing groove, and the plate is sealed with a sealing gasket, and is sandwiched in a fixed pressing plate, and the movable pressing is performed. Heat exchanger in the middle of the plate.

The device uses a cassette chip set technology that is not an ordinary plate. In each plate group, the non-hazardous medium flows on the side of the gasket and the dangerous medium flows in the middle of the welded plate. The combination of alternating gaskets and welding processes ensures that the media does not mix. A unique sealing system for high pressure and vacuum applications. There is a custom, damage-resistant annular gasket on the welded side. Our semi-welded plate heat exchangers have a long product life and provide safe, leak-free operation, greatly reducing the exposed gasket area.

Extensive experience and extensive process knowledge enable us to avoid the common pitfalls of complex applications and provide reliable, high performance heat exchangers.

Features:

The heat transfer characteristics of the detachable heat exchanger are retained.

The fouling factor is low.

Safe operation.

Washable.

Long lasting.

Application range:

Capacity range: 0.1m3/h to 2500m3/h

Operating pressure: ≤3.5MpaG

Operating temperature: ≤180°C

Plate material: stainless steel 304, 316L, Ti, Ti-Pd, 904L, SMO254, Hastelloy, nickel Ni

Gasket materials: NBR, EPDM, HNBR, FKM (VITON-A, VITON-B, VITON-G).

PRODUCTS

PRODUCTS SOLUTIONS

SOLUTIONS