Working principle:

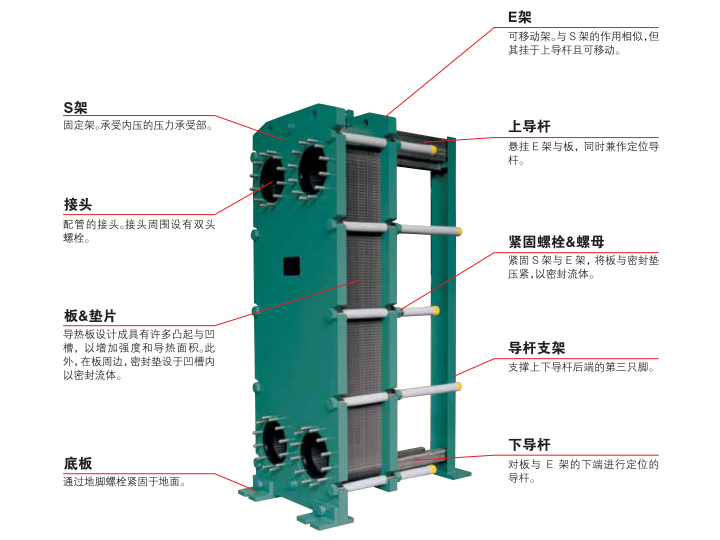

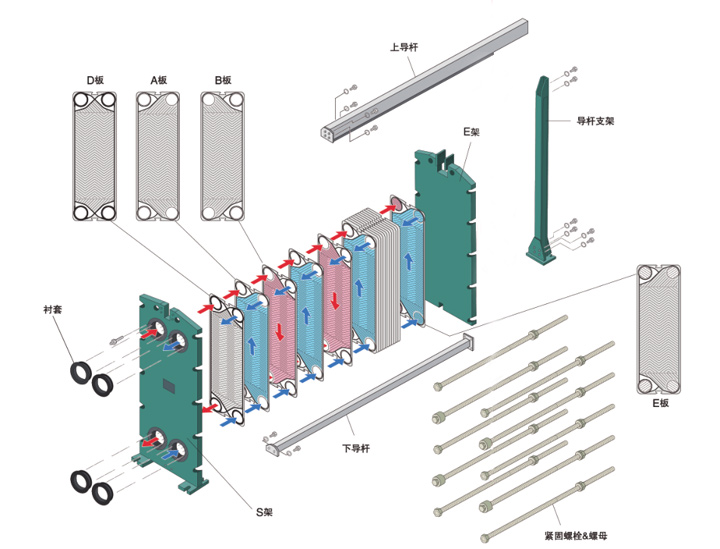

The plate heat exchanger is composed of a set of corrugated metal plates with four corner holes for the passage of two liquids for heat transfer. The metal sheet is mounted in a frame having a fixed plate and a movable pressing plate on one side and clamped by a clamp bolt. A gasket is placed over the plate to seal the fluid passages and direct fluid flow alternately into the respective passages to form a heat exchange. The flow, physical properties, pressure drop and temperature difference of the fluid determine the number and size of the plates. The corrugation of the plate not only increases the degree of turbulence but also forms a number of support points sufficient to withstand the pressure difference between the media. The metal plate and the movable compression plate are suspended on the upper guide bar and positioned by the lower guide bar, while the rod end is fixed on the support. On the column, but if one or both of the liquids pass through the heat exchanger more than once, the interface should be on the fixed plate and the movable compression plate. In most cases, one-way is used, and all the pipes are connected to the fixed platen. On, check the shoes to open the heat exchanger without disassembling the pipe.

Advanced panel structure:

Compared with other heat exchangers, the gasket detachable heat exchanger is compact; it can exchange heat at a temperature difference of 0.5-1 °C, designed up to 30 Bar, with a throughput of up to 4500 m3/h; improved sheet guide The flow design effectively prevents the scale from scaling and improves the heat transfer coefficient up to 8000w/m

2.k。

Changeable working conditions:

Rich plate type, various angles, various groove depths, different combinations to form a suitable heat exchanger suitable for working conditions, plate positioning system and single-side flow design and special clamping size marking. Easy to install and take over, run and maintain. Heat exchangers of different materials, such as stainless steel. Plates made of titanium or other special alloys to meet different industrial needs. Hot mixed form. By changing the flow pattern or increasing the number of flow channels, a myriad of combinations can be achieved, from a single flow of two fluids to a multi-flow flow of three or more fluids. Provide designers with a reasonable choice to meet different working conditions.

Visible economic benefits:

The plates are molded in a uniform manner and are made of high precision molds. Reduce the physical stress of the plate and improve the balance of the plate, greatly extending the service life of the plate; the plate is easy to access and easy to clean by hand. In many occasions, it can be cleaned by countercurrent rinsing. It does not take too much time for daily cleaning, and no special training personnel are required. All series adopt the paste-free form to reduce operation and maintenance costs and facilitate maintenance. The heat transfer and pressure can be adjusted, and the heat transfer coefficient and pressure drop can be adjusted through the combination of the plates to obtain a good heat transfer coefficient, thereby reducing equipment investment; economical, due to its high heat transfer coefficient, easy installation and maintenance, the initial stage Investment and operation and maintenance costs are greatly reduced.

The company has a rich portfolio of product models and specifications to provide a cost-effective and stable heat transfer solution for HVAC, refrigeration and industrial applications.

|

Plate material |

Suitable for fluid |

|

Stainless steel(304/316/316L) |

Clean water, river water, edible oil, mineral oil |

|

Titanium and titanium fertilizer(Ti/Ti-pd) |

Sea water, salt water, salt |

|

254SMO |

Dilute sulfuric acid, sparse salt solution, inorganic solution |

|

HASTELLOY(C276/D205/B2G) |

Concentrated sulfuric acid, hydrochloric acid, nitric acid |

|

Nickel(Ni) |

High temperature, high concentration caustic soda |

|

ALLOY |

Fluids that require special alloys to meet |

PRODUCTS

PRODUCTS SOLUTIONS

SOLUTIONS